1994 Porsche 928 GTS – A Modern Classic Restored

Impossible as it may be to believe now, during the 1960’s Porsche considered the 911 model to be coming to the end of its reign. Slow sales seemed to reinforce this idea, along with the rise in popularity of the luxury grand tourer. With this in mind, Porsche set their sights on a luxury grand tourer of their own, a vehicle that would blend the excitement and handling of a sports car with the comfort and attention to detail expected from a car designed to eat up the miles. And so, after much debate, the foundation of the 928 was laid on a front-engined, rear wheel drive chassis and the powerhouse driving it all was a water-cooled V8 engine.

Being water-cooled and front-engined, the 928 was a departure from Porsche’s roots and for purists, this layout negated any benefit derived from the increased comfort and practicality. Nevertheless, the 928 developed an avid fan following and managed a respectable eighteen-year production between 1972 and 1995. The GTS was the final swan song for this model, produced between 1993 and 1995. Featuring several upgrades over the previous iterations, the GTS boasted a 5.4 litre V8 delivering 345hp, producing 0-60mph in 5.4 seconds and ensuring the 928 model line went out with a bang! Years later, the 928 is enjoying a resurgence as Porsche’s most underrated and undervalued model, and the GTS version is the one to have!

The owner of this Iris Blue 928 GTS had recently added it to his collection which includes the previously featured Ford Sierra RS500 Cosworth (an extensive detail carried out as Part 1 & Part 2 – finished, as this 928 was, with Kamikaze Collection Infinity Wax Hybrid), an Aston Martin DBS and a Ferrari Testarossa. Although a highly sought after model, the paintwork was showing signs of neglect. Keen to have the vehicle restored to the standards deserving of a Porsche, the 928 GTS was booked into UF’s award-winning Brands Hatch Detailing Studio for a raft of treatments including Paint Correction, Alloy Wheel Refurbishment, Alloy Wheel Protection and Leather Care.

Even before the car had been through the decontamination and cleaning stages, the damage to the paintwork was evident to see. Swirls, many random deep scratches, machine polisher holograms, baked on water spot marks – the paintwork was covered in them. The water spot marks were particularly bad on the bonnet which, on the 928, is quite expansive! First, though, it did need a good clean as it was filthy! – Derek Ginger, Master Detailer, UF Detailing Studio

The usual decontamination processes were followed: first, Nanolex Wheel Cleaner & Iron Contamination Remover was applied to the bodywork to remove brake dust contamination. The active ingredient this product contains changes colour on contact with ferrous contamination. When the colour change deepens no further, the solution has reached its full potential and can be rinsed away, carrying with it the potentially harmful particles.

Elimination of sticky tar deposits and bug remains was achieved using Nanolex Tar Remover, a solvent-based specialist product which gets to work on tar and bitumen, dissolving the bonds which allow the deposits to grip the substrate. This was also used to loosen the glue holding the badges to the bodywork as these were tired and damaged, and required replacing.

To remove diesel splatters and other oil-based deposits, Gtechniq W5 Citrus All Purpose Cleaner was applied using a Kwazar Pump-Up Sprayer. Care was taken to ensure the wheel arches were fully covered with the solution, along with the boot, bonnet and door shuts. The areas around the catches were agitated with a detailing brush to loosen the greasy build-up. The solution was rinsed away with a carefully directed jet of water from a Kranzle K-1152 TST pressure washer.

The engine and engine bay were carefully degreased and cleaned, with care taken to ensure all openings that could allow water into the inner workings were protected.

In spite of the wheels being booked in for refurbishing, they still required careful cleaning to prevent any cross contamination when moving the car. A UF Wheel Bucket with Grit Guard was used, with a solution of Nanolex Wheel Cleaner & Iron Contamination Remover and Wheel Woolies Brushes. These long-handled brushes fit through the alloy wheel spokes to allow for cleaning through to the back of the rim.

Ultimate Snow Foam was applied to the bodywork and wheels through a Kranzle adapted foam lance. This slick solution creates a thick, rich foam which clings even to the vertical surfaces of the car, lifting larger particles of dirt and grit away and encapsulating them within the foam. These can then be rinsed away without further damage to the paintwork.

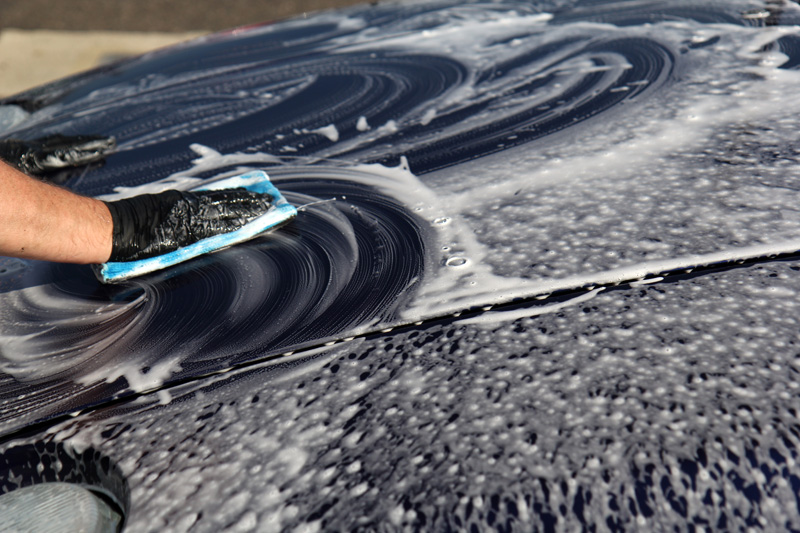

A second application of Ultimate Snow Foam was made and used as a lubricant for a clay mitt. The mitt shears away stubbornly bonded contamination to leave the surface of the paintwork feeling as smooth as glass to the touch. This is essential in order to maximise the level of gloss and reflectivity achievable when applying the final wax layer.

For paintwork to be as reflective as possible, it must be as uniformly even as is achievable. A flat surface will be far more reflective than a bumpy one, so removing any contamination which may affect the reflectivity is essential. For particularly stubbornly bonded particles covering large areas, shearing them away with a clay mitt is the most effective method of removal once all non-contact options have been used. – Derek Ginger, Master Detailer, UF Detailing Studio

After rinsing the foam and contamination away, the 928 GTS was washed using the Two Bucket Method. The employs two buckets with Grit Guards, one for wash water and one for rinse water. The wash mitt is rinsed in the Rinse Bucket between washing the car, to ensure dirt transferred away from the car is not reintroduced. This helps to reduce the opportunity for causing further damage to the paintwork.

Once clean, the 928 GTS was given a final, pure water rinse from an Aqua Gleam De-ionising Water Filter attached in-line with a hose. The car was dried using soft microfibres and brought into the detailing studio. Here, the nooks and crannies of the 928 GTS were blown through with an air blower to force out residual rinse water.

The 928 GTS was raised on a hydraulic ramp, the alloy wheels removed and sent away for factory quality refurbishing using a six-stage process matched to UF’s exacting standards.

To determine the true condition of the paintwork, a SCANGRIP Sunmatch light was used, the high-intensity beam highlighting deviations in the uniformity of the paintwork. Damage was recorded on the Vehicle Appraisal Sheet (VAS) for reference during machine polishing. Multiple paint depth readings were taken over each panel and the results indicated that the 928 GTS had in places been repainted at some stage during its twenty-three years.

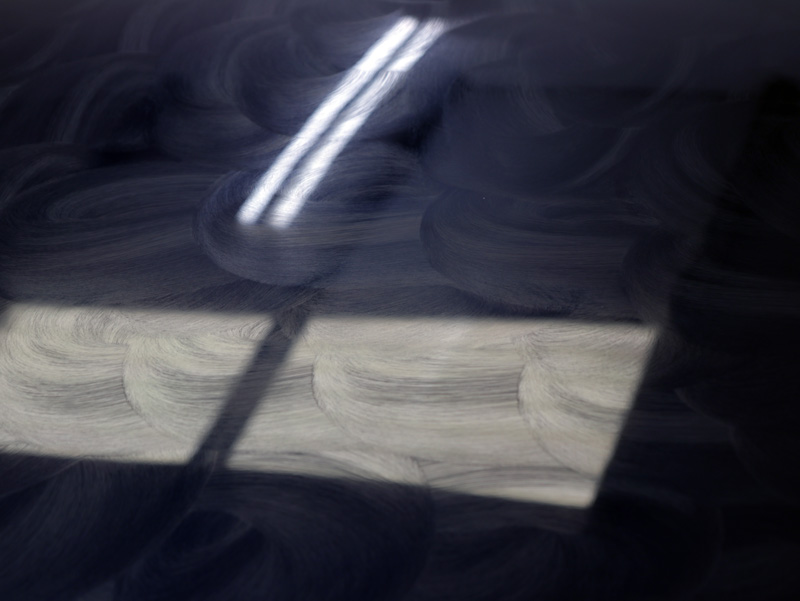

The inspection revealed a myriad of swirls, many random deep scratches (RDS) and buffer trails from previous machine polishing. Additionally, the water spot deposits had etched deeply onto the bonnet and the top of the wings, and attempts to remove them with designated water spot removers were unsuccessful. Typically, in instances such as this, the paintwork would have been wet-sanded. However, the paint depth readings had returned results that indicated the bonnet had been skimmed with filler and wet sanding the bonnet was therefore out of the question. The only option was to use an aggressive compound and pad combination. – Derek Ginger, Master Detailer, UF Detailing Studio

A RUPES BigFoot LHR75E Mini Polisher was selected as it is ideal for working on curvy and particularly damaged areas, generating increased cutting action by having a shorter throw. Using Menzerna Super Heavy Cut Compound 300 with a Flexipads Black Microfibre Pad, removing the water spot etching still took several hours. The remainder of the scratches and other paintwork damage were also eliminated using this combination, restoring clarity to the paintwork.

The paint finish was very easy to hologram and the colour of the paintwork showed them up clearly. As a result, it was imperative to work carefully and methodically, paying attention to the behaviour of the clearcoat. – Derek Ginger, Master Detailer, UF Detailing Studio

To refine the paint, a FLEX PE14-2-150 Rotary polisher was used at a moderate speed, with a Kamikaze Collection Banzai Dynamics Black Finishing Pad and Menzerna Super Finish Plus 3800. This brought the paintwork up to a highly burnished gloss. This finish was protected using a layer of Kamikaze Collection Infinity Hybrid Wax. A blend of high-quality natural carnauba wax and nano-ceramic elements, Infinity Hybrid Wax delivers all the reflective gloss expected from a carnauba based wax, with the pH tolerance and durability delivered by a ceramic coating. In tests, washing up liquid, neat degreasers and a pH11 alkaline failed to remove this hybrid coating! And the results when applied to the 928 GTS were nothing short of jaw-dropping.

Infinity is different to any other product: first, it must be mixed in the pot for sixty seconds prior to application in order to blend the natural and synthetic components and to activate the ingredients. Then, once it’s been applied, it must be left to cure for around ninety minutes to allow the protective elements to bond effectively with the paintwork. Then, it can be buffed off with a microfibre. – Derek Ginger, Master Detailer, UF Detailing Studio

With the wheels returned having been fully factory refurbished, they were wiped down with IPA before being protected with Kamikaze Collection Stance Rim Coat, as were the brake calipers and the wheel nuts. A nanotechnology-based ceramic coating, Stance Rim Coat is highly heat resistant so will not burn off when the wheels and their components become hot. Treated surfaces repel oils, dirt and water and inhibit the build-up of brake dust particles. Being easier to maintain, astringent cleaners are not necessary to remove contamination. Instead, wheels can be easily cleaned using a pH-balanced cleaner.

The wheels were replaced on the vehicle and then the new centre caps were put in place.

The leather was essentially in good condition with little sign of fading or abrasion. It did, however, require deep cleaning. For this step, Colourlock Leather Care products were selected. Colourlock is an internationally respected manufacturer of innovative leather care and repair products. If leather is cracked or torn, Colourlock is able to supply the means to repair the damage. If recolouring is required as a result of wear and tear, or UV fading, Colourlock can provide the correct dye specifically matched to your vehicle’s interior colour code.

Colourlock provides a Mild Leather Cleaner and a Strong Leather Cleaner. The Mild is strong enough to effectively clean all but the most soiled leather. As it is always a good idea to use the gentlest products to achieve the desired outcome, Mild Leather Cleaner was used and, in combination with a little bit of agitation using a Leather Brush, brought the leather up brilliantly. Then, to protect the finish, Colourlock Leather Protector was applied to help prevent the leather becoming dried out from UV damage. – Derek Ginger, Master Detailer, UF Detailing Studio

The new Porsche badges arrived and were replaced, giving the final touches to the extensive cosmetic overhaul.

UF Detailing Studio – Award Winning Detailing. Call 0333 800 8004 to discuss your requirements.