Brakes & Calipers – The Forgotten Components of Cosmetic Restoration

Recently, a customer brought his latest acquisition: a low mileage 2009 Mercedes-Benz SL350 into UF Studio for appraisal. A member of the Mercedes-Benz Owners Club, he was looking forward to the show season but first, the paintwork would require some restoration. Being Obsidian Black Metallic, every blemish showed up clearly, particularly in daylight. So, the car was booked in for a number of detailing services including Paint Correction, Glass Treatment and Leather Protection. Keen to ensure the final result would be as close to perfect as possible, he also opted to have the wheels and brakes completely refurbished to factory standard.

Full Wheel & Brakes Refurbishment

With the detailing works completed, the SL350’s paintwork looked absolutely stunning, however, this served to highlight the cosmetic condition of the brake hubs and calipers which were now letting down the overall appearance of the car.

We organised the refurbishment of the five spoke alloys and they looked better than new, but the brakes and calipers on this type of wheel are more visible than most. It’s likely a previous owner had used a highly acidic wheel cleaner. This, combined with the effects of road grime and road salts had caused oxidation. The rust was highly visible and the impact on the overall appearance of the SL350 could not be ignored. So, the decision was taken to remove them, paint them and take steps to protect them in order to prevent the same thing happening in the future. – Matt Back, UF Studio

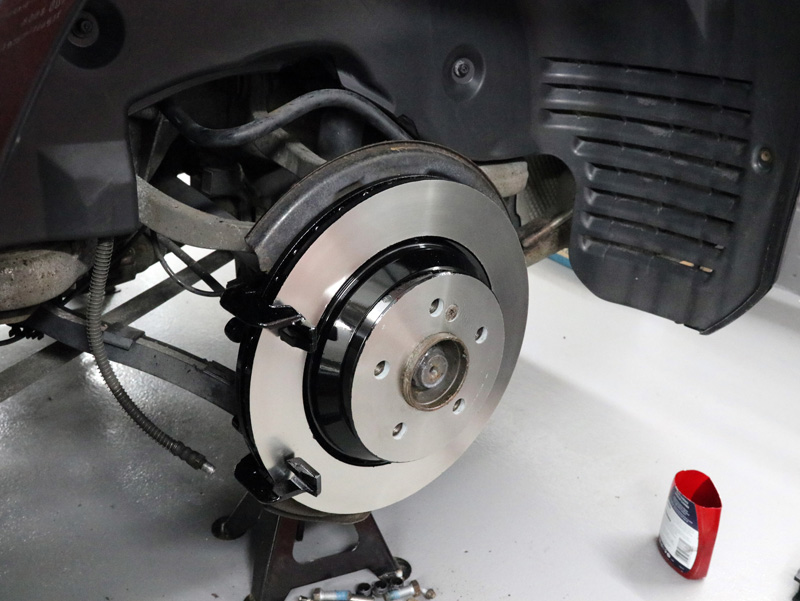

The mechanical work was entrusted to a Mercedes-Benz specialist who arrived to dismantle the brake system into its component elements.

The brake assembly needed dismantling so the parts could be replaced. However, the brake pad fixing pins had seized.

The fixing pins and the calipers are made of two different types of metal: pins are steel; calipers are made from cast aluminium. This is because aluminium as well as being strong has good heat transfer properties, so they do not retain heat in the same way other metals would. Both pins and calipers are heated and cooled repeatedly and this heat causes the two metals to weld together. – Mercedes-Benz Specialist

A light file was used to remove the corrosion and the caliper pins were cut so the brake pads could be removed. The calipers were removed and sent for treatment. First, they were degreased and decontaminated, and, using a chemical stripper, removing old paint and taking the surface back to bare metal. The calipers were shot blasted to etch the surface before being primed and the paint applied. Finally, applying a high quality clear coat lacquer completes the painting process.

Colour Coding Calipers & Hubs

After consulting with the owner, it was agreed the calipers should be colour-coded to match the paintwork.

New discs had been purchased and rather than leaving these as standard, the hubs were painted to match the calipers and bodywork. They were then lacquered for an additional layer of protection.

Protecting With Kamikaze Collection

Once the newly painted parts arrived back, the brakes could be reassembled. First though, the disc hubs and calipers were sprayed with Gtechniq Panel Wipe to ensure they were free from dust, polish and silicon residues. They were then sealed with Kamikaze Collection Stance Rim Coat, a nano ceramic coating capable of withstanding the ferocious temperatures hubs, calipers and wheels are subjected to. Stance is highly resistant to extremes of pH, limiting the potential for damage from road salts, harsh wash chemicals, and industrial fallout. Thus, areas that typically would have little or no protection now had paint, lacquer and sealant defending them against the elements.

As the calipers had been removed, air had become trapped in the lines requiring the system to be bled. Additionally, as the rear brake discs had been removed, the hand brake needed adjusting.

Brake fluid is hydroscopic, so it traps moisture from the air. So, the brakes were bled and new brake fluid added. Then, as the old brake discs were worn and so were thinner than the new brake discs, the hand brake was adjusting to accommodate the new, thicker brake discs. – Mercedes-Benz Specialist

Carefully, the brakes were refitted using a plastic coated torque wrench to preserve the newly painted finish from accidental ‘dings’. The rear calipers also had new securing springs fitted.

Whilst the brakes were being fitted, each refurbished wheel was treated with Panel Wipe before being comprehensively coated back and front with Kamikaze Collection Stance Rim Coat.

Once Stance had been allowed to cure, the wheels were refitted to the vehicle taking care to adhere to the correct torque settings. To complete the look, the tyres were dressed with Gtechniq T2 Tyre Dressing to provide a long lasting, natural satin sheen.

People invest a significant amount in having their vehicle’s paintwork restored but often, details such as the brake components are overlooked. However, having these parts refurbished or replaced, and taking the time to have them painted and protected can make an enormous difference to the overall finished appearance. An added benefit is, completing this step also helps preserve the final appearance for longer, inhibiting rust and making hard working wheels easier to keep clean during the weekly wash. And colour-coded calipers really do set the car apart from the others. It’s definitely going to be a head-turner this show season! – Matt Back, UF Studio

From start to finish Matt, Sean and the guys at UF were totally driven in delivering a truly professional product and that has been proven in the wonderful finish that you have produced for my Mercedes. My local Mercedes dealer wanted to see the car and was immensely impressed with the standard of work. Top job, top products, top people. Nothing else to be said. Paul S, Mercedes-Benz SL350 Owner

UF Studio – Award Winning Detailing. Call 01474 360 360 to discuss your requirements or complete the online enquiry form here to receive a bespoke no-obligation quotation by email.