Toyota GT86 Aero – Protected Using The Kaizen Approach

The Toyota GT86 D-4s Aero is nothing if not eye catching. The rattle of the exhaust will catch the ear, turn the head and the size of the rear wing will keep most petrolheads staring after the car as it makes its way down the street. The enormous rear wing and gaping front splitter come together to deliver a visually aggressive road presence. For dedicated fans of the Japanese performance car and lovers of the drift culture, the GT86 D-4s Aero is where it’s all at.

The appeal for most enthusiasts lies in the handling. It’s a rear-wheel drive, so the propensity for sliding around corners with the tail at right angles to the apex is huge, but with the engine set low in the engine bay, the balance is everything you might expect from a Toyota / Subaru collaboration. The GT86 Aero is quite simply, great fun to drive. Even the notoriously hard to please Jeremy Clarkson enthused, “Everything about the GT86 is immediate – and brilliant. It will put a smile on the face of every motoring enthusiast in the world.”

With the paintwork on this red GT86 Aero beginning to look dull, the owner booked his car into UF’s Brands Hatch Detailing Studio for a Gloss Enhancement. This involves a 2-stage machine polishing process to remove paintwork blemishes such as random deep scratches (RDS), acid rain etch, oxidised paint and wash-induced swirls, all of which cause gloss levels to drop, making paintwork look dull and tired. Once the blemishes have been removed and gloss restored, the paintwork is then protected using a ceramic coating. On this occasion, the owner opted to upgrade to the Platinum sealant option, which uses Kamikaze Collection ENREI Coat.

Kamikaze Collection is a Japanese designer of innovative ceramic coatings and ENREI Coat is their flagship sealant. Manufactured using the Japanese ‘Kaizen’ philosophy of continuous improvement, ENREI provides unrivalled protection and gloss. The coating itself must be applied following strict methods and under tightly controlled environmental conditions. As such, ENREI Coat is available as a service only through Kamikaze Collection trained and certified detailers. In addition to machine polishing and protecting the paintwork, the owner also specified Fabric Protection, Clear Vision Glass Treatment and Alloy Wheel Protection.

It seemed appropriate that the GT86 should receive a high-quality, Japanese engineered ceramic coating. Japanese paintwork tends to be quite soft and therefore it really benefits from a hard durable protective coating. ENREI Coat is a two-stage system that delivers scratch and swirl resistance, extreme water beading to repel water-borne contamination, as well as being virtually impervious to extremes of pH, the better to withstand etching from acid rain fallout. Additionally, ENREI further enhances the colour and gloss of the paintwork, so the final results are show stopping! – Derek Ginger, Master Detailer, UF Detailing Studio

Before commencing machine polishing, the GT86 Aero first required thorough decontamination to remove not only the surface dirt but also the hidden contamination such as iron particles and diesel splatters. The GT86 Aero was dirty, with fallout and contamination caught in many tight crevices.

First, as natural traps for dirt, the number plates were removed to allow for more comprehensive cleaning.

Bilt-Hamber Korrosol, a specialist product containing an active ingredient that targets iron particles was sprayed onto the bodywork and wheels. Iron particles are usually derived from brake pads which shred when the brakes are applied. The tiny, hot shreds become aerosolised and attach to the first substrate they encounter, bonding fast. Rather than rubbing at them with a wash mitt, an often unsuccessful method of removing them, Korrosol’s active ingredient shrinks the particles, forcing them to break the bond with the substrate and allowing them to be easily rinsed away. Then, using Gtechniq W7 Tar & Glue Remover, the bodywork and wheels were treated for sticky contamination. The car was raised at each corner, in turn, using a trolley jack, to produce clearance between the tyres and the wheel arches, allowing for them to be thoroughly degreased, then treated for tar and iron contamination.

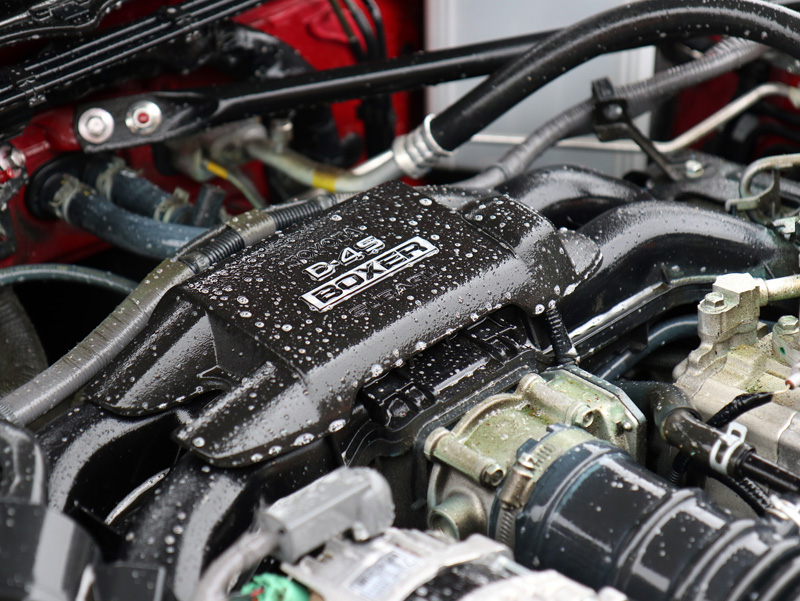

After rinsing, the engine bay was then cleaned using Bilt-Hamber Surfex HD to remove the build-up of greasy grime.

The whole car was subsequently degreased to eliminate oil-based contamination that has the potential to cause staining on the paintwork and would interfere with the final sealant if not removed.

After another rinse, the GT86 Aero was pre-cleaned using Ultimate Snow Foam applied through a foam lance attached to a Kranzle K-1152 pressure washer. The thick, creamy lather clings, even to vertical surfaces and lifts dirt and grit away from the panels, encapsulating them within the foam. The foam and contamination can then be rinsed away before a wash mitt comes into contact with the panels. With the excess dirt removed, it is much safer to wash the vehicle as there is less contamination to become trapped in the wash mitt and be dragged back and forth, the leading cause of wash induced swirl marks.

With decontamination and pre-wash complete, the car was washed using the Two Bucket Method. This involves keeping soapy wash water separate from the rinse water. Both buckets have a Grit Guard in the bottom to rub the mitt across in order to dislodge trapped dirt particles, preventing them from being rubbed back onto the paintwork. The wash mitt is dunked into the Wash Bucket, loaded with the soapy solution, and a section of the car washed. The now dirty mitt is then rinsed in the Rinse Bucket, wrung out, then dunked back into the Wash Bucket and the process repeated until the car is completely clean. The GT86 Aero was rinsed clear of suds before an Aqua Gleam De-ionising Water Filter was connected in-line with a hose to deliver a final pure water rinse. The car was initially dried using soft microfibre towels and brought into the detailing studio where an air blower was then used to force trapped water droplets from all the crevices.

The paintwork was inspected using a SCANGRIP Sunmatch lamp, the high-intensity beam revealing all the marks which were then noted on the Vehicle Appraisal Sheet for reference during the machine polishing stage.

The paintwork had a few swirls and scratches but there weren’t any severe defects. Given that Japanese paintwork is typically quite soft and that this GT86 Aero had a solid, rather than metallic paint finish, I knew the paint would probably correct easily but be more challenging to refine. I had to experiment with different compounds before I hit on the right combination to produce the results I wanted. I needed an oily compound as the paint was quite dry and many of the initial compounds I tried were water-based and didn’t suit the paint. – Derek Ginger, Master Detailer, UF Detailing Studio

For the correction process, a RUPES LHR 12E Duetto dual action polisher was used with a Kamikaze Collection Banzai Dynamics Red Polishing Pad and Menzerna 2500 Medium Cut Polish, a compound specifically designed to remove defects from softer paintwork.

Refining the paintwork was carried out using a Kamikaze Collection Banzai Dynamics Black Finishing Pad with Kamikaze Collection Ichiban Finishing Polish. With fine diminishing abrasives, Ichiban removes the micro-marring and leaves a high gloss finish.

The panels were wiped with Gtechniq Panel Wipe to remove polishing residues. Then, the No 1. Primer Base Coat of ENREI’s two-step system was applied by hand, allowed to cure for five minutes before being buffed off. The base coat smoothes the paint’s surface leaving it completely uniform and acts as an anchor for the top layer. After allowing the base coat to cure for around two hours, the No.2 Top Coat was applied, allowed to cure for ten minutes before final buffing with Kamikaze Collection lint-free edgeless microfibres.

The secret to ENREI’s performance is not only the formulation but also in the method it is applied. Kamikaze Collection has very specific guidelines as to how the coatings should be laid down and buffed off. Failure to apply and remove the residues in the stipulated manner will result in inconsistent results. In addition, there are set parameters for humidity and temperature and attempting to apply the coating outside of those parameters will interfere with the curing process. Lately, the weather has been unusually humid, so the conditions inside the studio had to be tweaked to bring them to within ideal tolerances. – Derek Ginger, Master Detailer, UF Detailing Studio

Whilst ENREI was curing, the wheels and calipers were wiped clean of any residues before Kamikaze Collection Stance Rim Coat was applied. This hydrophobic and oleophobic coating inhibits the build-up of damaging brake dust. The highly heat resistant formula means the barrier persists, even when the wheels and calipers heat up. In addition, Stance Rim Coat is highly resistant to degradation by chemical means, so harsh winter conditions and astringent wash chemicals will not remove the coating.

The interior of the GT86 Aero features a lot of Alcantara, a luxury material that is also very easy to mark.

The upholstery and carpets were cleaned using Colourlock Alcantara & Textile Cleaner and then allowed to dry, after which Gtechniq I1 AB Smart Fabric Coat was applied. This cures to form a water-resistant barrier, helping to protect the interior materials from accidental staining from liquid spills. Additionally, I1 AB provides an anti-bacterial protection to help keep the interior germ-free.

The windows were coated with Kamikaze Collection Intenso Window Coat.

As every driver has experienced, driving in rainy conditions, particularly over long distances, can be extremely tiring. For a while, window sealants have been around that help to bead water, but many are tricky to apply and also can cause the wipers to judder. Intenso has an extra-slick formulation, so it’s easy to apply and doesn’t cause the judder or squeaking. Water beads even when driving at relatively low speeds, improving driver comfort and safety. – Derek Ginger, Master Detailer, UF Detailing Studio

To protect the trim, Solution Finish Black Trim Restorer was applied. This dressing uses advanced polymer technology along with innovative ingredients to produce a long-lasting, deep black finish that protects from chemical and UV fading.

Exhaust tips are at the dirty end of the business, so it’s hardly surprising they become tarnished with soot. To bring them back to a sparkling shine, Britemax Easy Cut Metal Polish was used. Containing a combination of solvents, chemical cleaners and fine abrasives, Easy Cut quickly breaks down soot, grime and tarnish to reveal a bright, shiny metal surface. To protect the finish, Britemax Final Shine Metal Sealant was applied.

With all the surfaces now protected, the final touch was to apply Gtechniq T2 Tyre Dressing to give the tyres a natural satin sheen.

UF Detailing Studio – Award Winning Detailing. Call 0333 800 8004 to discuss your requirements.